How Epoxy Flooring Makes Your Factory Safer

How Epoxy Flooring Makes Your Factory Safer

The safety of yourself, your employees, and your visitors are crucial to any factory’s success. Safety is the number one concern in these demanding work environments due to the hard work and sometimes hazardous conditions required to get the job done.

Therefore, these businesses need a strong floor that ensures the safest conditions possible! That’s where epoxy flooring comes in. These floors can make your factory safer in several ways!

In the article below, we’ll discuss exactly how epoxy flooring can make your factory safer. Continue reading to learn more!

Slip-Resistance

A common misconception regarding epoxy floors is that they’re slippery. This misconception formed due to the glossy finish epoxy has and a few assumptions. However, this isn’t the case! A basic epoxy floor is no more slippery than concrete.

If your factory is frequently exposed to wet conditions and slip-resistance is a concern, epoxy flooring offers options to mitigate this problem. There are several add-ins that can be included in an epoxy floor that offer better skid-resistance.

Not to mention, decorative flake epoxy flooring is always an option that can help your slip-resistance! These epoxy floors are created by layering acrylic chips over the epoxy primer and finishing the floor with a thin, clear epoxy topcoat. These flakes give the floor more texture and better traction. As a result, your factory can have a floor that’s beautiful and safe!

Reflectivity

Factories are often somewhat darker environments due to their large, open spaces, lack of windows, and sparse lighting. This can lead to a lack of visibility and, sometimes, result in injuries.

Thanks to epoxy flooring’s naturally reflective surface, these floors can reflect the light in your factory, making it much brighter! This dramatically increases visibility and can even save your company money on its utility bills by reducing the number of lights needed for proper visibility!

As a result, you’ll notice a significant difference in the visibility within your building. You may even see improved production numbers thanks to the brighter, more comfortable environment for your employees!

Color-Coded Customization

Epoxy flooring is highly customizable. There are limitless colors and patterns to choose from to meet your facility’s needs! In an industrial environment, this customization can be utilized to improve safety throughout your factory.

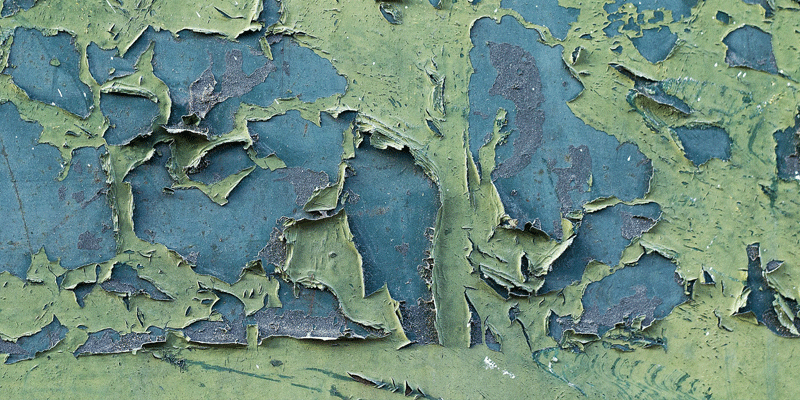

Many factories use color-coded walkways, equipment paths, and restricted areas to advise employees and visitors of where they can safely be. However, these areas are typically marked by painting the floor, which is usually concrete. The problem with this is that paint fades and flakes away in a short time. This leads to frequent repainting or even the lack of repainting, which eventually results in a lost-time accident.

When you choose epoxy flooring, the floor is integrally colored throughout and will not fade or flake away. This leaves a permanent, vibrantly marked walkway, equipment path, or restricted area that will keep your employees and visitors safe!

Superior Durability

You may be wondering, “How can the floor’s durability make it safer?” The answer is simple. When your factory has a floor that’s easily damaged, this damage leads to trip hazards, such as deep cracks or chipped areas that form holes.

Epoxy flooring is remarkably durable as it can withstand high impacts, rough abrasions, and high volumes of foot and vehicle traffic without sustaining significant damage. This means your factory will drastically reduce the risk of trip-and-fall injuries common with easily damaged floors.

Finishing Up

Epoxy flooring can drastically improve safety in any factory! With its slip-resistance, reflectivity, color-coded customization, and superior durability, your factory should stay on track with production and happy, healthy employees!