Simple Tips for Repairing Garage Epoxy Floors

Simple Tips for Repairing Garage Epoxy Floors

By taking the time to repair your epoxy floor, you can help to extend its life and prevent future damage. If you are not comfortable repairing the floor yourself, you can always call a professional to do it for you. There are plenty of professional epoxy flooring companies that can help you get the job done right. Epoxy floors are very durable, but they can be damaged and worn out over years of use. When this happens, it is important to repair the floor so that it can continue to protect your investment and provide a safe surface to work on.

This article will provide some simple tips for repairing garage epoxy floors and ways to maintain them so that they last for years to come.

What is Epoxy Flooring and Where is it Common?

Epoxy flooring is a type of flooring that is made up of multiple layers of epoxy resin. It is common in both commercial and industrial settings because it is very durable and resistant to many different types of damage. This type of flooring can be found in factories, warehouses, showrooms, garages, and even some homes. The look of epoxy flooring can range from completely clear to a variety of different colors and designs. It is also possible to get epoxy flooring that has a non-slip surface, which is ideal for areas where there is a lot of foot traffic or where liquids are often present.

How to Repair Damaged Epoxy Flooring?

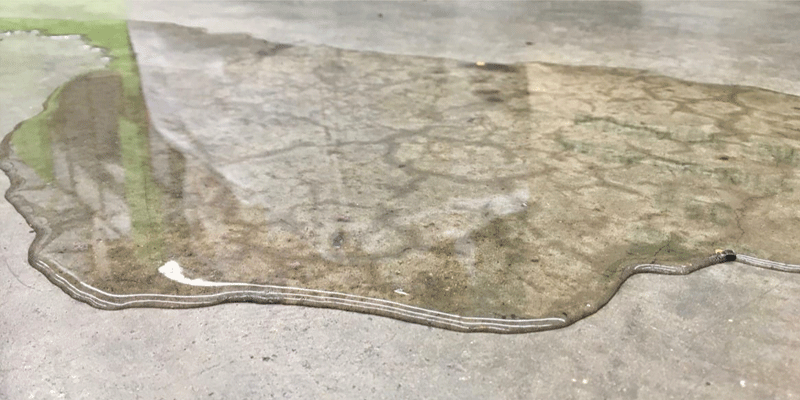

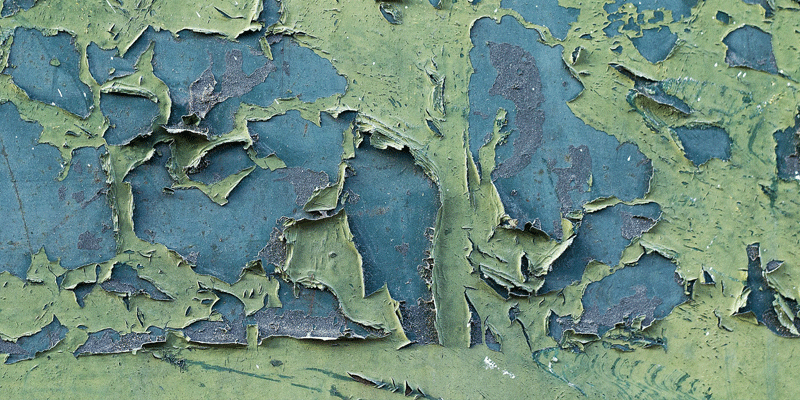

One of the most common ways that epoxy floors become damaged is from heavy traffic. Over time, the weight of vehicles and other equipment can cause cracks and chips in the flooring. If you notice any damage to your epoxy floor, it is important to repair it as soon as possible. The longer you wait to repair the damage, the more likely it is to spread and become worse. Here are some of the most important tips for repairing garage epoxy floors:

– Use a putty knife or another sharp object to remove any loose pieces of epoxy from the floor. Be sure to dispose of these pieces properly so that they do not become a trip hazard. It’s best to use a dustpan or broom to sweep them up.

– Clean the area around the damage with a degreaser or soap and water. This will help to remove any dirt, grease, or debris that could prevent the epoxy from bonding properly. A clean surface is essential for a successful repair.

– Mix together the epoxy resin and hardener according to the manufacturer’s instructions. Be sure to mix them together thoroughly so that they will cure properly. Instructions for mixing can be found on the packaging of the epoxy or online.

-Use products that are specifically designed for repairing epoxy floors. These products can be found at most hardware stores or online. Knowing how to repair garage epoxy floors is important for maintaining the life of your investment.

-If the job is way above your head, don’t hesitate to call a professional. A professional can come and assess the damage and give you an estimate for the repair. They will also be able to do the job quickly and correctly so that your floor looks as good as new.

-Do plenty of research before you hire a professional. Make sure that they have experience with repairing epoxy floors and that they use high-quality products. You should also get multiple estimates before you decide on a company to do the repairs.

Why is Repairing Epoxy Floors Important?

Repairing garage epoxy floors is important for a number of reasons. First, epoxy floors are an investment. They can be expensive to install, so you want to make sure that they last for as long as possible. Repairing damage when it first occurs can help to prevent the need for more extensive and expensive repairs down the road. When epoxy floors are well-maintained, they can last for many years. Another reason why repairing epoxy floors is important is for safety. Epoxy floors that are cracked or chipped can be very dangerous. They can cause trips and falls, which can lead to serious injuries.

Whether you are a business owner with an epoxy floor or a homeowner, it is important to know how to repair garage epoxy floors. By following these simple tips, you can keep your floor looking great and prevent costly repairs in the future. Epoxy flooring is a great investment, so it is important to take care of it. If you have any questions about epoxy flooring or need help with a repair, be sure to contact a professional or do plenty of research online. There are many resources available that can help you learn more about epoxy flooring. Knowing how to repair them and keep them looking their best will help you enjoy them for many years to come.

ories and warehouses anymore. It’s becoming increasingly popular in residential settings as well, thanks to its low maintenance and high durability.

ories and warehouses anymore. It’s becoming increasingly popular in residential settings as well, thanks to its low maintenance and high durability.