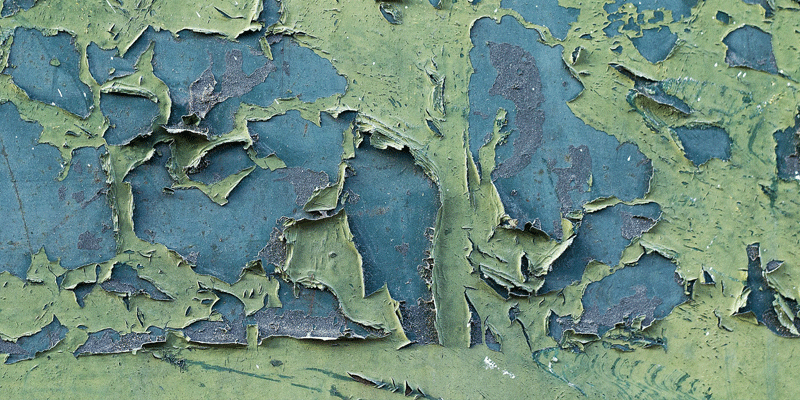

Peeling Epoxy Floors: Repairs and Prevention

Peeling Epoxy Floors: Repairs and Prevention

You may be wondering what can cause peeling epoxy floors. This article will discuss some of the common reasons for this problem and how to fix them. Also, read on to learn about the best ways to prevent this problem from happening again! Follow these steps to make sure your floors stay beautiful and protect their investment.

Problems with Peeling Epoxy Floors

There are many reasons why you may experience problems with peeling epoxy floors. Whether it is improper preparation or the wrong application, a poorly prepared floor can lead to peeling epoxy. Concrete flooring needs to be free of debris, sand, and oil before an epoxy coating can be applied. If the floor is not completely clean, the epoxy may pull away from the concrete and cause round holes and fisheyes. Here are some tips to help prevent this problem.

When applying epoxy, you should ensure that you are applying it evenly. Otherwise, you risk discoloration or a yellowed floor. Mixing the resin and activator correctly is essential in minimizing the chances of peeling and blistering. Make sure to follow all safety guidelines while applying the material to prevent damage to your floor. If you’ve tried mixing the epoxy yourself, you may be disappointed with the end result.

In addition to improper application, improper preparation can lead to peeling and discoloration. Poor preparation and improper mixing of the flooring compound can cause the floor to peel and become a tripping hazard. Proper prep is critical to preventing these issues. Ensure the floor is thoroughly clean before applying the coating. Make sure to use a quality primer and choose the proper coatings and paints to prevent peeling.

Before applying the epoxy coating, it’s important to prepare the concrete. If the concrete is wet, moisture can cause peeling and bubbling. Removing grease, oil, or petroleum-based lubricants on the floor is also important. This may also cause a floor to have fish eyes. Lastly, if the floor is not completely dry, air entrainment will cause the surface to crack and peel.

One of the most common reasons for garage floor epoxy to peel is improper preparation. Properly prepared concrete will be easier to apply and remove than poorly prepared one. Proper preparation can prevent problems with peeling epoxy floors by improving concrete’s porosity and cleaning ability. Incorrect preparation can also lead to uneven color. For example, improper concrete preparation can cause peeling epoxy to crack. Proper preparation and testing are crucial to ensure the floor will be durable and long-lasting.

Prevention

To avoid the problem of peeling epoxy floors, you should ensure that the floor is completely dry before putting on the coating. The epoxy will not adhere to a wet or dirty concrete floor, so you should always make sure the floor is clean before applying the coating. This process will also increase the adhesion of the epoxy coating to the concrete surface. Peeling epoxy floors can occur once the coating has been applied. If you don’t follow these instructions, you may end up with a floor that peels after a few months.

Another common cause of peeling epoxy floors is improper floor preparation and environment. If the concrete is not properly prepared, the epoxy will not adhere properly and may cause round holes or fisheyes in the finish. To prevent peeling epoxy floors, make sure that you have a smooth and level surface. In addition, the environment should be ideal, with the right temperature and humidity. If the weather is too hot or too cold, the epoxy will not adhere to the floor.

When applying epoxy, be sure to clean the floor thoroughly. Even if you live in a climate-controlled environment, the resin may still peel after a few weeks or months. To avoid peeling epoxy floors, clean the floor well before the professional arrives. Using water for a day or two before the application will allow the epoxy resin to dry and cure before the professional can start working on the installation. In addition, if the floor is porous, don’t use water right before the application date, as it may dry and cause the adhesive to fail.

Another common cause of peeling epoxy floors is moisture. While moisture can’t penetrate the epoxy coating, water vapor can. This causes hydrostatic pressure to lift the coating off the surface. You can spot signs of moisture problems by looking for dark spots or efflorescence on the floor. Additionally, if the slab is below grade, you should always check it with a moisture test. If you notice any of these symptoms, you should immediately take action.

Preventing peeling epoxy floors starts with a clean garage floor. Make sure to sweep away any dirt and debris accumulated on the floor. If you can’t remove the dirt and dust, use a commercial degreaser to get rid of the oil stains. This will ensure that the epoxy coating lasts for many years. If you follow these tips, you can prevent peeling epoxy.

Repair

In many cases, a small crack or fissure in an epoxy floor can be repaired with a standard epoxy floor paint kit. While this repair process may require a few hours, it can also correct the problem. While cracks can be repaired by resurfacing the entire floor, more minor cracks and scratches are easier to correct. Here are some tips to repair a small crack or scratch:

Sand the area using a palm sander. This is especially useful for edges that are close to the wall. You should leave the floor to dry for 24 hours before applying another layer of epoxy. A good hand sander is available at most home supply stores. Then, using the hand sander, apply another coat. Allow the floor to dry thoroughly before stepping on it. When finished, you should use a 2-part epoxy.

If you have localized problems, patching the area instead of ripping out the floor is a good idea. While this solution might be easier than tearing out the entire floor, it will leave visible seams that will pick up dirt. If you have trouble patching, consulting a licensed professional for assistance may be worth consulting. And don’t forget that epoxy floors are costly! If you have a small budget, you can choose to replace your existing floor with a new one, but that’s not always an option. And if you can’t afford a new floor, you might want to repair your old flooring material to keep it in good condition.

One thing you should know about epoxy flooring is that it’s highly sensitive to temperature changes. Because it hardens rapidly when it comes into contact with hardeners, it can also cause peeling or chipping in areas. Therefore, before attempting to repair a peeling epoxy floor, you must first check whether the substrate is sufficiently solid before applying the epoxy coating. Ensure that the substrate has a consistent moisture content, as too much humidity can cause a problem with the epoxy’s adhesion.

Now that you have a better understanding of epoxy as a material and how to prevent peeling, you can decide if an epoxy coating is right for your floors. Contact us today and receive a free estimate on epoxy installation and maintenance.